The fiber laser technology

Generator: The traditional CO2 resonator, with its scheduled maintenance

requirements and its high energy consumption, is replaced by a high-brilliance laser

generator (aka fiber laser generator). It does not use any special gas for the generation

and emission of the beam and it does not require, therefore, turbines or compression

systems. No scheduled maintenance is required, thus reducing operation costs

dramatically. Energy consumption is also drastically reduced with a wall plug efficiency

of over 35%.

Beam Delivery: The fiber laser beam is delivered, from the generator to the

cutting head, directly within an optical fiber (feeding fiber) thus eliminating

any energy dispersion. Mirrors or pressurized nitrogen paths are not

needed, making the beam delivery very simple. No maintenance is required,

hence no cost to the user.

Cooling unit: CY2D systems include a cooling unit to manage the fiber laser generator temperature control. This chiller

is much smaller compared to those used in for the CO2 lasers, and use a fraction of the energy. Minimal maintenance

required annually.

Cutting head EVO III

This is a CYLASER OWN design and built cutting head specifically developed

for the fiber laser technology. No compromise. The machine features one

single lens cutting head. The cutting head also features automatic height

and focus adjustment, eliminating the need for alignments and head

changing. The cutting head is mounted onto the Y axis transversal

component. The Z axis used to raise and lower the head to the appropriate

height for cutting or travel has a 120 mm (4.7’’) range of motion. Additional

features of the cutting head include, break-away torch (no breaking parts or

consumables) with no tools need restore, integrated cooling system for heavy

usage, HRC High Back Reflection Control, ACF Automatic Sheet Finder and

Nesting Alignment, AFR Automatic focal point adjustment, CHC Capacitive

Height Sensing Control, SLM Etching System in 4 different power levels, ABS

pierce air-blow jet, NCS Automatic Nozzle Cleaning, RMS Micro Junction

Management, SZP Axis Origin Point Setting, FCM Fly cut module, CSP Cylaser Servo Piercing System.

This is a linear motor machine not a rack and pinon

Made in Italy

Approx New Cost $500k

CY2D40LM3015 (5’x10’)

System Working area

X Axis mm (in) 3100 (122’’)

Y Axis mm (in) 1550 (61’’)

Z Axis mm (in) 120 (4.7’’)

Loading Capacity on each pallet Kg (lb) 700 (1540)

Speed

Maximum Axis Acceleration g (in/s2 ) 4 (1544)

Maximum positioning speed parallel axis X/Y in/min 5,906

Maximum positioning speed simultaneous axis X/Y in/min 8,268

Precision

Repeatability in 0.00098

Positioning Accuracy (over 10 inch travel) in 0.0019

Laser Nominal Power kW 4.0

Power Consumption kW 12

Cutting Range

Carbon Steel mm (in) 25.4 (1.00)

Stainless Steel mm (in) 15 (0.59)

Aluminum mm (in) 15 (0.59)

Brass mm (in) 8 (0.31)

Complete

System

Overall Dimension Area

Length mm (ft in) 11299 (37’ 0.9’’)

Width mm (ft in) 3000 (9’ 10’’)

Height mm (ft in) 2199 (7’ 2.6’’)

Weight (ancillary equipment excluded) Kg (lb) 11000 (24250)

Total Installed Power (generator, chiller & dust collector included) kW 30

Color RAL 7040 Gray

5015 Blue

Power Supply 480 V. 60 Hz. (or on

request)

Optional Equipment

Code Description Price

GTA00001-00 System set-up for compressed air assisted cutting (on-board filters and

valves)

USD 2,500.00 INCLUDED

CMS00027 Scheduler allows the possibility to manage and realize different working programs in

sequence

USD 3,400.00 INCLUDED

Other Options

Code Description Price

Automatic Nozzle Changer ANC 6 positions (3015L/4020L) USD 7,100.00 INCLUDED

CAF00003 Dust Collector (for distances greater than 8 meters, a technical evaluation must be

carried out on the required exhaust filter model) up to 8kw

USD 13,600.00 INCLUDED

Automation

Code Description Price

Scrap conveyor and Set-up for automatic load unload system

It allows to retrofit at a later date the system with an automatic load\unload unit.

It includes:

- SCHEDULER

- PREPARATION FOR RETROFITTING OF AUTOMATIC NOZZLE CHANGER

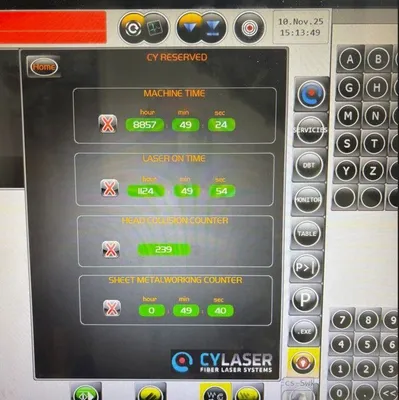

LOW HOURS

We use cookies to improve your experience. Privacy Policy.